Company Overview

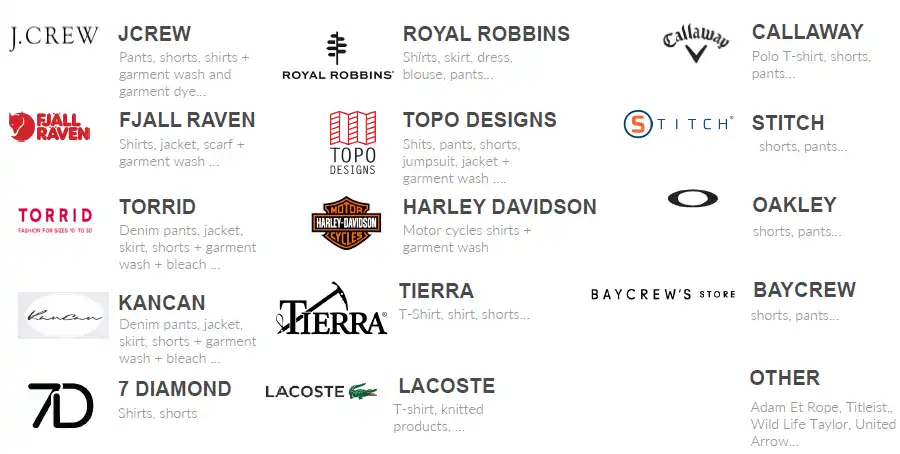

Founded in 2000, The Blues, One Member Limited Company has become one of Vietnam’s premier garment manufacturers and retailers, trusted by leading global fashion brands. With more than 200 retail stores across Vietnam and partnerships with renowned names such as J.Crew, Torrid, and Fenix Outdoor, The Blues has built a strong reputation for quality, innovation, and reliability.

For over two decades, our success has been driven by a commitment to product development, strict quality control, and advanced technology. We focus on exceeding customer expectations, ensuring that every garment meets international standards. Our dedication to sustainability for both employees and the environment, combined with a proven record of on-time delivery, makes The Blues a trusted partner in the global apparel supply chain.

The Blues Head office

Location:

359 Le Van Sy Street, 13 Ward, 3 District, Ho Chi Minh City, Vietnam

Website

https://theblues.com.vn/

The Blues Denim & Washing

Location: Lot 8, Dien Nam Dien Ngoc Industrial Zone, Dien Nam Bac Ward, Dien Ban District, Quang Nam Province, Vietnam

Company Size: 45,000 m² | 3 sewing manufactories | 2 laundries

Sewing Capacity

- 5-Pocket Jeans: 300,000 pcs/month

- Basic Casual Jackets: 120,000 pcs/month

Washing & Dyeing Capacity

- Denim Wash & Effects: 350,000 pcs/month

- Whisker, PP Spray, Grinding, Destroy, Bleach, Wrinkle

- Dyeing: 300,000 pcs/month

With large-scale manufacturing capacity and advanced laundry technology, The Blues Denim & Washing provides creative finishing solutions that enhance denim products while meeting strict global quality standards. Our focus on eco-friendly washing techniques ensures sustainable practices without compromising style or durability.

The Blues Woven + Knitted

Location: Road No. 02, Hoa Khanh Industrial Zone, Lien Chieu District, Da Nang City, Vietnam

Company Size: 17,290 m² | 3 manufactories | 1,500 employees | 18 hanger lines, 8 single lines

Sewing Capacity

- Pants & Shorts: 150,000 pcs/month

- Shirts & Dresses: 300,000 pcs/month

- T-Shirts, Knitted Pants & Shorts: 10,000 pcs/month

The Blues Woven + Knitted specializes in a wide variety of woven and knitted garments, offering both large-scale and customized production. With modern facilities, skilled workers, and efficient production lines, we deliver apparel that reflects comfort, durability, and international style standards.

Technology & Innovation

At The Blues, we invest in cutting-edge technology to ensure precision, efficiency, and flexibility across all operations. Our advanced equipment includes:

- Automatic Spreading Machines

- Auto Cutters

- Laser Cutting Machines

- Computerized Auto Sewing Systems

- Hanging Line Systems

- Laser Finishing Machines

- Dry Ozone & Wet Ozone Treatments

- E-Flow & EIM Technology

These innovations allow us to create garments that not only meet customer requirements but also support sustainable production methods.

Why Choose The Blues

- Over 20 years of industry expertise

- Strong global partnerships with top fashion brands

- Wide production capacity across denim, woven, and knitted garments

- Advanced technology for innovation and sustainability

Proven reliability with on-time delivery

With its integrated manufacturing network, advanced facilities, and commitment to sustainable growth, The Blues continues to lead Vietnam’s garment industry while serving a global clientele. Whether it’s denim, woven, or knitted apparel, we deliver products that inspire confidence and set new benchmarks in quality and innovation.

MACHINES & EQUIPMENTS

1. Auto Spreading and Cutting Machine

Our Vector fabric cutting room combines lean-oriented production processes with maximum uptime, ensuring both speed and precision. This technology enables:

- High cutting quality and performance

- Increased material savings

- Reduced running costs

- High productivity with up to 98% uptime

Improved product quality at the lowest cost per cut

2. Hanger Production System

The hanger production system revolutionizes garment assembly by focusing on single-piece flow rather than traditional bundles. Fully computerized, it utilizes an overhead transportation system that automatically routes and delivers cut pieces to each sewing station. This system also:

- Records all data at each workstation

- Provides real-time insights for Management Planning & Control

Ensures higher efficiency, accuracy, and streamlined workflow

3. Laser Machine

Our advanced laser technology replaces manual processes and reduces the use of harmful chemicals, improving both worker safety and environmental protection. The system includes:

- Rofin Sinar Laser Unit

- High-speed galvo motor & mirrors

- 3D focusing system for precision

- Continuous projection marking system

- Servo-controlled automatic lift system

- Four table changer system for efficiency

- Temperature-controlled cooling system

- Multilingual control & automation (English, Turkish)

This ensures high precision, speed, and consistency in garment finishing.

4. Dry Ozone Technology

This system transforms air into ozone and circulates it inside a tumbler, providing an eco-friendly finishing method. Benefits include:

- Cleaning garments without water or chemicals

- Reducing base color naturally

Preventing back-staining (especially for denim garments)

5. Wet Ozone Technology

Wet ozone offers a chemical-free bleaching and fading process in a single step. It delivers:

- Color reduction and unique washing effects

- Zero waste, as ozone reverts back to regular air

- An environmentally safe alternative to traditional bleaching methods

Current business – The Blues

Reference products

Contacts:

COMPANY PRESIDENT

Mr. Lam Quang Thai

+84 938 200 970

+1 714 2669908

thai@theblues.vn

SALES & PLANING DEPT

Denim + washing

Ms.Mai Tien

+84 909 582 628

maitien@theblues.vn

Ms.Bach Tuyet

+84 905 767 827

bachtuyet@theblues.vn

SALES & PLANING DEPT

Woven + knitted

Ms.Mai Ngoc

+84 905 417 419

maingoc@theblues.vn

Ms.Thanh Trinh

+84 937 322 042

theblueshk.trinh@gmail.com